RCA Rt ❯ Toolbox Scalability Real life use ⇢ 5WHYS+A3 12STEPS+CauseTree 7QT ⇢ Training

12STEPS+CauseTree

Utilise the power of teamwork and discover the root cause(s) of your issues. Generally, this powerful structured approach will be sufficient for more than 90% of investigations.

INTRODUCTION A HELICOPTER VIEW → STAGE 1 STAGE 2 STAGE 3 → ESCALATION

- Lead to a clear focus for the investigation,

- To find the real causes (the “root” causes) for the issue under investigation and

- To create actions and countermeasures that will eliminate or reduce the problem to a tolerable level.

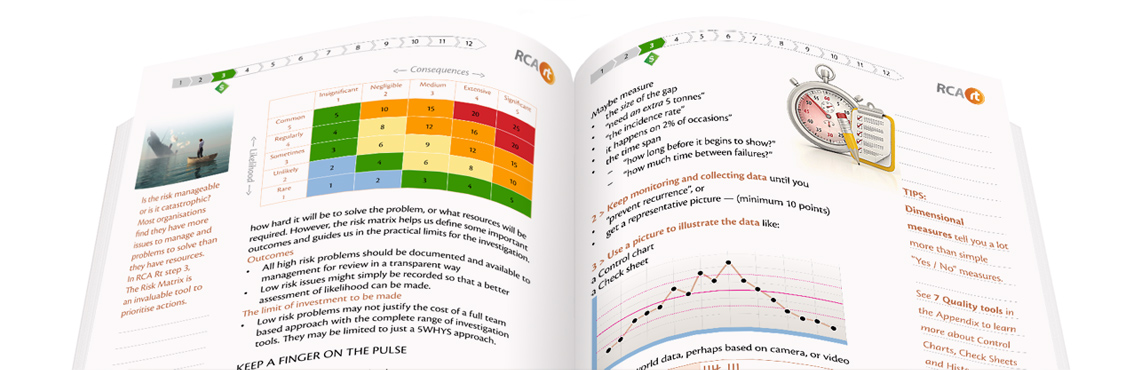

To help us imagine where and how 12STEPS + CauseTree can be used, we have illustrated the universe of problems, defined by dimensions of Risk and Complexity, showing where it fits within a continuum, from trivial to critical. Generally, this structured approach will be sufficient for more than 90% of investigations.

To better understand and efficiently implement 12STEPS + CauseTree, you will require

- Managing problem complexity and workload through good understanding of risk.

- A team approach to problem solving

- Foster a no blame culture through proper understanding of mistakes, slips, reducing of errors and learning from errors.

A very well designed course covering a well structured, formal method of problem solving. Very well presented.

—onesteel

RCA Rt (12STEPS) should be mandatory from the top down, throughout the corporation.

—rio tinto

The team exercises were great. They really pulled everything together.

— SILCAR

A HELICOPTER VIEW

Topics in the course are easy to follow, textbooks and visual tools are provided and used as in real investigation scenarios:

When a problem is presented — whether it confronts you directly, or someone asks you to investigate — you should first define exactly what you need to change, or prevent from recurring. Problem definition should give a clear target and a strong focus on a single goal/problem.

Even when a problem has many parts, teams achieve more by focus- sing on one important issue, than by tackling several targets simultaneously. Aiming at multiple targets almost guarantees confusion: it’s better to solve a sub-problem and apply the lessons later. As soon as the problem is defined, and the focus is sufficiently tight, we assess and monitor data to give us a basis for comparison, and to detect improvement or deterioration from the state when the alarm was set off.

It’s an uncomfortable fact of business that expensive failures are often caused by well-intentioned but rapid initial responses to problems. They succeed in keeping the operation running but, all too soon, they lead to unexpected side effects that can result in massive losses and untold harm to customer relations.

Therefore we must confirm containment, confirm that the initial response — e.g. turning off the machine, isolating the product, or using a back-up valve, etc. — will protect the customer and not cause unexpected side effects.

After the problem has been defined, the target has been achieved, there is a “peg in the ground”, and the initial response to the problem has been verified, finding real causes can proceed.

This stage begins with the search for possible causes by having a good practical look at the process and by asking the people directly concerned what happened?, what changed? This is followed by making comparisons and finding patterns in the data.

The team can then brainstorm for potential causes on the basis of genuine knowledge. The ideas generated from brainstorming are built into a cause tree to determine what leads to the problem.

The cause tree begins with the event that must be prevented from recurring — or the condition that must be changed — and works back through the chain of causes until the initial system failures (root causes) are identified.

Evidence ensures the validity of the cause tree and a genuine ability to prevent recurrence.

Potential solutions are developed to prevent occurrence or to change the system. Brainstorming identifies solutions that may be more cost effective but could otherwise be overlooked.

The best solution must still be authorised and all involved will need to understand what is happening. The changes will need to be implemented and adjustments may be needed as well.

After a suitable time, the changes must be checked to ensure they have resolved the issue as planned.

Finally the project can be completed by assuring the change is embedded in the system and people are recognised and congratulated for their contribution.

STAGE 1: FOCUS (steps 1, 2, 3 and 4)

In this stage of the process we- define the issue, and

- focus on one problem, so we can

- put a peg in the ground, and

- confirm containment to protect the people, plant, environment and customer

- clearly define the problem, so that it is understood by everyone,

- start data collection,

- assess impact and prioritise work,

- verify containment actions.

STEP 1. DEFINE THE ISSUE

The is, the should and the gap. Is the issue one-off event or ongoing condition?

STEP 2. PICK THE TARGET

One place, one process, one problem.

STEP 3. ASSESS AND MONITOR

Assess the impact. Keep a finger on the pulse.

STEP 4. CONFIRM CONTAINMENT

Does the safety net and the temporary fix stop the problem from spreading? Look for side-effects.

STAGE 2: FIND CAUSES (steps 5, 6, 7 and 8)

In this stage of the process we search for possible causes by- Taking a good, practical look and collecting data

- Finding patterns and comparisons in data, and

- Brainstorming for causes.

- CauseTree and 5WHYS.

- gather evidence,

- arrange the raw data to show patterns,

- identify possible causes,

- and understand causal relationships so that suitable countermeasures may be chosen to overcome the problem defined in Stage 1.

STEP 5. PRACTICAL LOOKE

Find out what happened. Look at the process. Ask the people, ask what has changed.

STEP 6. PATTERNS & COMPARISONS

Use 7 Quality Tools (7QT) to visualise gathered data.

STEP 7. BRAINSTORM FOR CAUSES

Every idea is a good idea. Use checklists and 7 Quality Tools.

STEP 8. BUILD A CAUSE TREE

Check the flow from cause to effect. Test for switch on and off. Check for evidence.

STAGE 3: FIX FOREVER (steps 9, 10, 11 and 12)

In this stage of the process we fix the problem forever by:- Selecting the cause (or causes) to eliminate

- Determining an appropriate change

- Preparing and executing the change, and

- Confirming that it worked.

- “Make it stick”, by building the fix into the system.

- generate solutions,

- implement necessary changes,

- ensure that the changes are effective, and

- become a permanent part of the system.

STEP 9. SELECT A CHANGE

Remove the cause? Neutralise the effect? New technology? Eliminate the need?

STEP 10. PREPARE & EXECUTE

Get the authority. Explain, execute & fine tune.

STEP 11. DID IT WORK?

Collect data and evaluate.

STEP 12. MAKE IT STICK

Let the system know. Install warning signals. Learn from the solution. Thank everyone who helped.